Introduction

Lead has been commonly used for thousands of years because it is widespread, easy to extract, and easy to work with. It is highly malleable and easily smeltable. Metallic lead beads dating back to 6400 BCE have been found in Asia Minor. Since then, the metal has been used by many ancient peoples. A major reason for the spread of lead production was its association with silver, which may be obtained by burning galena, a widespread lead mineral.Lead mines were worked in 2000 BCE in the Iberian peninsula [ ... ] and also in Greece, Carthage, and Sicily. With the development of mining and its territorial expansion in Europe and across the Mediterranean, Rome became the greatest producer of lead during the classical era, with an estimated annual output equaling 80,000 tonnes. The Romans obtained lead mostly as a by-product of extensive silver smelting. Lead mining occurred in Central Europe, Britain, the Balkans, Greece, Anatolia, Sardinia, Sicily, and Hispania, which alone accounted for 40% of world production. Lead was used for making water pipes in the Roman empire and consequently the Latin word for the metal, plumbum, was the origin of the English word "plumbing" and its derivatives. Even though some Romans, such as Vitruvius, were able to recognize its danger for health. Lead was easily available in the Roman society, and as such, its social status was low.

From: Wikipedia 2016

Processing lead

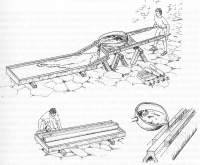

The principle steps in the production of lead pipes (for a.o. aqueducts) are- Mining, often as 'galena' ore, of lead together with silver. Special techniques were used like hushing and ground sluicing. In hushing (see Pliny NH 33.75)

water was collected in large tanks fed by aqueducts and was then released in a wave to pour down over the deposits. This removed the overburding, exposing

the mineral deposits, and also removed mining debris.

In ground sluicing a more controlled, contnuous supply of (aqueduct) water was used to wash out the ore and remove the overburden.

From: Adkins and Adkins: Ancient Rome(2004). - The next step was extraction (separation) of the (silver and) lead from the ore. This was done by smelting with charcoal in a fire or furnnace. The smelted lead was isolated and poured into molds to form ingots, which - after cooling down - could more easily be handled.

- Transport. Very often the mine was not in the vicinity of the place where the lead should be applied, so transportation (by cart) was necessary. It is hardly to imagine how in ancient times great volumes of ore have been transported over low quality roads to the customers or to a habour in the vicinity (if available).

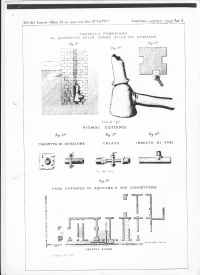

- production on the site; lead pipe inscriptions, see Vienne

- application (in towns and siphons): put on place, soldering

Production and application of lead pipes

|

About lead pipe production, see A. Cochet and J. Hansen (1986): Conduits et objects de plomb Gallo-Romains de Vienne (Isère)(in: Gallia Supllement nr 46 (1986) pag 23 - 50). More about inscriptions on lead pipes and (a) metal workshop(s) in Pompeii, see Bruun (2012): Stallianus, a plumber from Pompeii (and other remarks on Pompeian lead pipes), (in: Phoenix vol 64-1/2 - Classical Association of Canada (2012) pag 145 - 157). About the lead pipe inscriptions in Rome, see the PhD-theses of G. de Kleijn-Eijkelestam (2001): The water supply of anctient Rome: City area, Water and Population. |

Lead for the aqueducts of Lyon (France)

Lead pipes were a major element in the water supply within Roman towns and cities. On the other hand, and in particular in the West, lead pipes were applied in so-called siphons, as in the 9 siphons in the four aqueducts of Lyon (France).It has been said that, based on calculations from Germain de Montauzan 1908, echoed by Smith 1976 and Hodge 1983, some 10.000 - 15.000 tons of lead were needed, but it never was recalculated.

Hodge's conclusions were: (see Hodge 1992 pag 348-9):

- Total weight of lead of all the siphons at Lyon is 10.000 - 15.000 ton

- Total length of all Lyon siphon pipes: 150 km (9 pipes per siphon)

- Mean weight (if all pipes had the same characteristics): 67 - 100 kg/m (154 - 230 kg/10 ft)

Lead poisoning

Vitruvius (1st c BCE) warns us for the effects of lead poisoning, both during production of lead pipes, and the application in the water supply.But remember that lead was also used as flavouring wine and applied in cosmetics.

|

Earthen pipes have these advantages, first as to the work; next, that if damaged any one can repair it. Water conducted through earthen pipes is more wholesome

than that through lead; indeed that conveyed in lead must be injurious, because from it white lead is obtained, and this is said to be injurious to the human system.

Hence, if what is generated from it is pernicious, there can be no doubt that itself cannot be a wholesome body. This may be verified by observing the workers in lead, who are of a pallid colour; for in casting lead, the fumes from it fixing on the different members, and daily burning them, destroy the vigour of the blood; water should therefore on no account be conducted in leaden pipes if we are desirous that it should be wholesome. That the flavour of that conveyed in earthen pipes is better, is shewn at our daily meals, for all those whose tables are furnished with silver vessels, nevertheless use those made of earth, from the purity of the flavour being preserved in them. From: Vitruvius De Architecture Book 8, Chapter 6, 10-11 |

Major reasons to decline the hypothesis that lead poisoning took place at a larger scale: First, the calcium carbonate deposit that formed so thickly inside the aqueduct channels (so-called sinter) also formed inside the pipes, effectively insulating the water from the lead, so that the two never touched.

Second, because the water was constantly running, it was never inside the pipes for more than a few minutes, and certainly not long enough to become contaminated.

From: Hodge 1981 pag xx

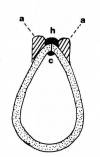

Sizes of Roman lead pipes

according to Frontinus. His introduction to this reads (chapter 37-38):|

I have listed below the standard sizes of all 25 pipes, although only 15 of them are in common use. These figures reflect the methodical system of which I have spoken,

and I have corrected those four pipes which the water-men modified. All pipes to be put into use in future should conform to these exact specifications.

If the anomalous sizes remain in place, their actual capacity should be reckoned in quinariae. Pipes not used are so noted in their respective cases. Translation: R.H. Rodgers 2003 |

| Lead pipe sizes | |||||

|---|---|---|---|---|---|

| Chapter | Name | Diam (cm) | Perim (cm) | Area (cm2) | Capacity (Q)* |

| 39 | quinaria | 2,31 | 7,26 | 4,19 | 1,00 |

| 40 | senaria | 2,77 | 8,71 | 6,04 | 1,44 |

| 41 | septenaria | 3,23 | 10,16 | 8,22 | 1,96 |

| 42 | octonaria | 3,70 | 11,61 | 10,73 | 2,56 |

| 43 | denaria | 4,62 | 14,52 | 16,77 | 4,00 |

| 44.1 | dudodenaria | 5,54 | 17,42 | 24,14 | 5,76 |

| 45 | quinum denum | 6,93 | 21,78 | 37,72 | 9,00 |

| 46.1 | vicenaria | 9,32 | 29,31 | 68,31 | 16,29 |

| 47 | vicenum quinum | 10,43 | 32,77 | 85,39 | 20,36 |

| 48 | tricenaria | 11,42 | 35,89 | 100,47 | 24,43 |

| 49 | tricenum quinum | 12,33 | 38,77 | 119,55 | 28,51 |

| 50 | quadragenaria | 13,19 | 41,44 | 136,62 | 32,58 |

| 51 | quadragenarum quinum | 13,99 | 43,96 | 153,70 | 36,65 |

| 52 | quinquagenaria | 14,74 | 46,34 | 170,78 | 44,79 (?) |

| 53 | quinquagenarum quinum | 15,46 | 48,60 | 187,86 | 44,79 |

| 54 | sexagenaria | 16,15 | 50,75 | 204,94 | 48,87 |

| 55 | saxagenum quinum | 16,81 | 52,82 | 222,02 | 52,94 |

| 56 | septuagenaria | 17,44 | 54,82 | 239,09 | 57,02 |

| 57 | septuagenum quinum | 18,06 | 56,75 | 256,17 | 61,01 |

| 58 | octogenaria | 18,65 | 58,61 | 260,09 | 65,17 |

| 59 | octogenum quinum | 19,22 | 60,41 | 290,33 | 69,24 |

| 60 | nonagenaria | 19,78 | 62,16 | 307,41 | 73,31 |

| 61 | nonagenum quinum | 20,32 | 63,87 | 324,49 | 77,38 |

| 62 | centenaria | 20,85 | 65,53 | 341,56 | 81,45 |

| 63 | centenum vicenum | 22,83 | 71,77 | 409,88 | 97,75 |

)* basic unit is the quinaria.