Construction

Construction of roads, bridges, and aqueducts required four elements: higher authorities to make the initial decisions, technical experts to put the decisions into practice, the correct materials and labourers to do the actual work. Decision making, planning, construction, obtaining and fashioning the materials each required different and sometimes specialised skills. It is easy to dismiss technical skill for the first of the elements as unlikely in this day of managerial theory, however the Roman system did not permit an individual to reach the highest ranks without training and experience. As early as the 4th century BC the positions of public office had been arranged into an orderly progression known as the cursus honorum. The normal course began with a period of military service, then a quaestorship or more probably a series of appointments such as aedile, praetor and possibly even consul, followed by censor and in some cases dictator. By 180 BC minimum ages had, rather sensibly, been set for higher positions. We also have evidence that at least two higher officials had technical skill, Marcus Vipsanius Agrippa - to whom Augustus granted many well-deserved honours for his remarkably varied accomplishments - and Sextus Julius Frontinus (O'Conner, 1993:36). Both had marked influence in the construction and administration of aqueducts in their time, and appeared to be men of high competence and energy. In the opinion of Hauck (1988:46) the Roman engineers had no formal understanding of force vectors and their resolution, shear and bending moment, the nature of stress, tension or compression, and other basic engineering principles. Probably then, their knowledge was developed empirically. Strong intuition and experience must have played a role.Gravity driven

Most ancient aqueducts were gravity systems. That is to say that they did not employ any means of pumping or moving water besides that of gravity in the aqueduct system, except perhaps for testing and water diversion during maintenance. By ensuring the source was higher than the termination, and by plotting a course for the aqueduct which maintained a uniform downward gradient, the water would flow purely by gravity. This required a detailed knowledge of the terrain. Engineers had to maintain a uniform slope while bridging valleys and tunnelling through hills. This required skilled surveying and the construction of detailed maps (Heiken, Funiciello & De Rita, 2005:143). This provides evidence for the high level of Roman planning. Possessing the skill is a necessary skill, but without a method of planning and control, the aqueducts could not be built.For most of their length the aqueducts were simply channels (rivus or specus) or tunnels, or less commonly pipes. The depth of the channel below ground varied so as to maintain a constant, shallow gradient throughout the length of the aqueduct. Vertical shafts were bored at intervals to provide ventilation and access. Only in the final stretches were aqueducts raised on arches, to give sufficient head for distributing water in the city. In order to maintain the shallow gradient the aqueducts did not take the most direct route to Rome, but followed the contours of the land and heading along spurs that led towards Rome. Tunnels were only resorted to when the fall from source to termination was too slight for a longer circuit around an obstruction, like a hill or mountain. In time, Roman engineers became more daring in the construction of high arches to support the conduits across valleys and plains. Some of the later aqueducts were as much as 27 metres off ground level. Closed pipes were occasionally used to span valleys using the inverted siphon method. Pressure forced the water down and up again on the other side of the valley, but to a slightly lower level than before. This system was costly as it required lead pipes and it was difficult to make joints strong enough to withstand the considerable pressure exerted by the water.

Herodotus (3.60) gives us a clear Greek precedent for the Roman techniques in the astonishing aqueduct built at Samos by the Megarian named Eupalinos, at the order of Polycrates. Herodotus describes it thus:

... a tunnel nearly a mile long, eight feet wide and eight feet high, driven clean through the base of a hill nine hundred feet in height. The whole length of it carries a second cutting thirty feet deep and three broad, along which water from an abundant source is led through pipes into the town.The Samos aqueduct is 1036 metres long, approximately 2.4 metres square. It was dug from two openings, with the two working groups meeting in the centre of the channel. The construction started in 530 BC and took about ten years. The error was only 60 cm. The workers faced problems with the unstable soil and had to deviate from the original course; they still managed to determine the correct path to the opposite working team. The deviation was 200 metres away from a straight line connecting the ends of the tunnel. Around 7000 cubic meter rock were removed from the mountain. Using the text of Herodotus, Guerin (1856) uncovered the entrance of the aqueduct. Between 1971 and 1973 the German Archaeological Institute of Athens uncovered the entire tunnel (Kienast, 1977 & Tsimpourakis, 1997).

Channels

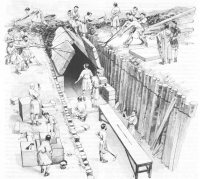

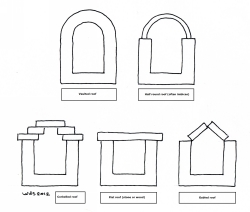

The typical Roman aqueduct was a close to surface channel in that it followed the surface of the land, instead of being raised on arches or sunk beneath it in a tunnel (Hodge). The channel was usually fifty centimetres to one metre below the ground, deep enough to afford some protection but shallow enough to provide access when repairs were required. Vitruvius specifies three types of conduit, namely masonry channels, lead pipes and terracotta pipes. By far the most common channel was masonry. The channel was built using the "cut-and-cover" principle rather than directly tunnelling it. Essentially, a hole was dug, the channel constructed, and then covered. This is quicker, easier and cheaper than tunnelling. In cross-section, the conduit normally formed an oblong, taller than it was wide.The size of the conduit varied, but the Marcia (90 cm wide by 2.4 m high) and the Brevenne (79 cm wide by 1.69 m high) give an idea of the averages. A vault usually formed the roof. Less commonly a pair of tilted flat slabs where used to form a pointed roof. The reason for these proportions is practical. The channel had to be accessible to a man for maintenance and cleaning, and it was this factor and not the volume of water to be carried that governed its size (Hodge, 2002). About the level in a channel: it was normally only one half to two-thirds full of water anyway, and was never intended to carry more.

Channels could be open or closed. Occasionally aqueduct channels were open to the air, especially when they traversed rock. A benefit of using channels was that they could be smaller than the conduits that ran on arches. Those conduits were large enough to allow men in them for maintenance purposes. An open channel could be a little smaller, as there would be enough space for a man to manoeuver if the roof was removed - a relatively easy process in the case of stone slabs and vaulted ceilings.

So the general principle was - as indicated above - to construct aqueduct channels in the 'cut-and-cover' technique in a trench. To cross a shallow depression in the landscape the channel, in order to keep its constant gradient, was built on a substruction - to a maximum height of 2 meters - or if necessary to put it on a series of arches: an arcade, like the well known construction of the Aquae Claudia and Anio Novus close to Rome, see the chapter Rome in Aquasite.

The maximum height was a channel of the aqueduct of Nimes (France) on a bridge on the level of almost 50 meters above the river Gardon: the famous Pont du Gard. Sometimes, to prevent such enormous height differences, a siphon was applied. [wds]

Lining

The floors and walls were lined with waterproof plaster, often called opus signinum. The plaster was usually not all the way to the roof, but only as high as the water would actually rise. The function of the plaster was threefold, to make the channels impervious to leaks or seepage, to provide a smooth, friction-free contact surface and to make the contact surface continuous and uniform with no joints from one end of the aqueduct to the other. As well as performing these functions, the plaster had to be strong and resistant to cracking, whether from heat expansion, freezing or other causes. The plaster also had to be able to cure while wet (Hodge, 2002). The plaster was typically installed in layers, and the last layer was polished. There were three reasons for polishing it. Firstly, to inhibit the formation of lime deposits and to make the removal of such deposits easier. Secondly, to harden the top layer and thus protect the other layers. Thirdly, to process the particles of lime and marble to form a horizontal orientation which prevents cracking due to shrinkage (Hodge, 2002). Both the composition and the installation were therefore very complex tasks, the ingenuity of which must not be underestimated (Hodge, 2002:98).From the thesis of Evan J. Dembskey on The aqueducts of Ancient Rome